Mobility and railway vehicle technology

Our activities in the field of mobile applications and drives include packaging, mechanical integration, design and strength testing for individual components, propulsion units and even entire vehicle structures.

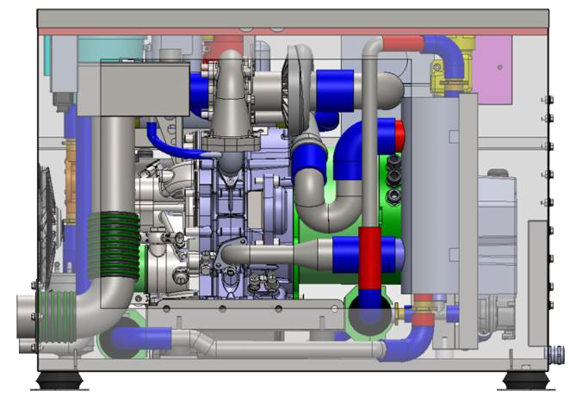

In the propulsion field, we design entire drive units using customer-specific components (motor, gear unit, cooler, ...) in specified designed spaces, optimise strength and monitor the series launch in cooperation with customers. Propulsion units of this nature are referred to as PowerPack and are used in commuter trains, speedboats and large excavators/construction vehicles.

In the vehicle field, our tasks range from design/concept and construction to weight-and strength-optimised realisation.

- Local/long-distance trains

- Repair vehicles

- Locomotives

- Structure gauge/packaging

- Operator's cab

- Brake

- Interior fittings

- Bogies

- Propulsion units

Energy and propulsion technology

Energy storage and propulsion technology are further central topics of our long-standing development work on PowerPacks, gensets and gas transport systems.

We develop supporting structures for battery modules, including integration into the vehicle. In terms of gas storage tanks, we commonly use pressure vessels made of fibre composite material. They are used as natural gas tanks aboard vehicles with combustion engines or as hydrogen tanks for fuel cell vehicles.

In addition, we also develop range extenders for hybrid electric vehicles. These technologies are used in passenger cars, trucks, buses and rail vehicles.

For both local storage and gas transport, several pressure tanks are interconnected to form a complete system. ISATEC develops customer-specific racks or frame constructions for standard ISO containers.

- PowerPack

- Support structures for battery modules

- Hybrid drives

- Genset

- H2 high-pressure tank filling

- Natural gas storage

Mechanical and plant engineering

A great success for ISATEC in plant engineering: The development of a portal milling machine for use in aircraft construction with two vertical axes (metal-cutting or water-jet cutting) for machining wings with up to 40 m of length. The challenge in this area is to combine high precision with short cycle times at a total weight of 60 tons.

ISATEC often designs, engineers and optimises machines and systems which have to meet high requirements, with safety concerns or investment risks playing a crucial role.

Typical applications include:

- Tool machines

- Presses

- Kneading machines/mixer shafts

- Separators

- Hydraulic cylinders/components

- Large fans

- Stranding rotors

Lightweight construction and fibre-reinforced plastic composites

ISATEC handles a variety of lightweight construction tasks – for both plastic and metal-based constructions. In addition, there are solutions using a mix of materials, e.g. in sandwich designs. In composite components, fibre reinforcements are used in a targeted manner to ensure that the power flow is correct.

Applications range from vehicle structures, superstructures, attachments, components and hybrid tool machines to fibre-reinforced pressure tanks.

In the context of rail vehicles, weight optimisation to increase loading capacity or to comply with weight limits is always a top priority.

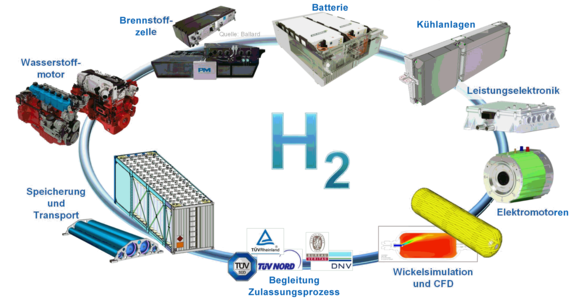

H2 / Renewable Energies

Since its foundation, ISATEC has been working on various topics related to renewable energies, optimized energy conversion and hydrogen technologies. What began with reactors for biological hydrogen production soon found its logical complement in the storage of hydrogen at 700 bar. Since the 1990s, numerous gas cylinders have been developed for the automotive industry, for plant manufacturers and suppliers. In parallel, complete tank systems for mobile and stationary applications, piping and distribution systems as well as complete system layouts were processed.

With our tool ISA-HyPlan, complete Power2Gas plants or hydrogen-based drive solutions can be technically and economically evaluated and optimized.

- Fiber composite high-pressure tanks, Type3, Type4

- Einstein-Telescope

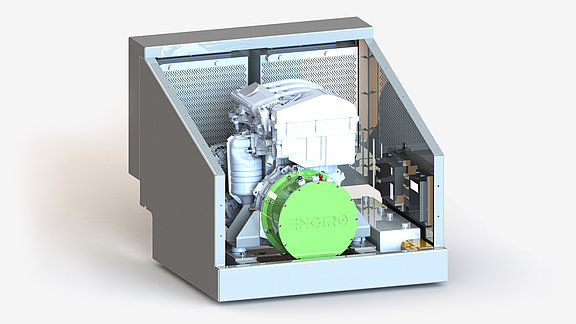

- HYPP (Hydrogen Power Pack)

- Photovoltaic

- Customised vehicle racks

- Container transport solutions

- Detail solutions for highly loaded components

- Crash simulations

- Filling and withdrawal simulation for hydrogen tanks

- P&ID, Piping and safety concepts

- System simulation with real data / Sector coupling solutions

Research and science

In addition to tasks from many branches of industry, we also handle a wide range of topics from research and science.

In the “HIS” research project funded by the Federal Ministry of Economics and Technology (BMWi), ISATEC and our project partners are cooperating on the development of a highly integrated stack module for high-temperature solid oxide fuel cells (SOFCs).

Within the framework of the National Hydrogen and Fuel Cell Technology Innovation Programme (NIP II) of the BMVI, ISATEC is working on the Delfin research project to explore alternative materials and manufacturing processes for cost and weight-reduced type-4 hydrogen pressure vessels (700 bar) made of continuous fibre-reinforced plastic.

In the context of the project “Development of optimised cooling geometries using adjoint simulation methods for direct hot water cooling of data centres”, which is funded by the central innovation programme for small and medium-sized companies (ZIM) with funds from the BMWi, thermodynamically and hydraulically optimised cooling geometries are developed using computer-aided simulation methods.

In another research project, “HyFly”, completed in March 2020 and funded by the German Federal Ministry of Economics and Technology (BMWi) as part of the aviation research program LuVo v-3, ISATEC conducted system studies on distributed hybrid propulsion systems for aircraft in collaboration with our project partners. Thanks to profound systems expertise, ISATEC and ENGIRO GmbH, are partners of choice and a source of ideas for high-performance generators and electric aircraft engines.

- Proprietary ISATEC R&D projects

- AMS experiment

- CMS experiment

- Research projects

- Large-scale flow simulations

- Wide-ranging relations to universities and research institutions