ZIM: development of optimised cooling geometries using adjoint simulation methods

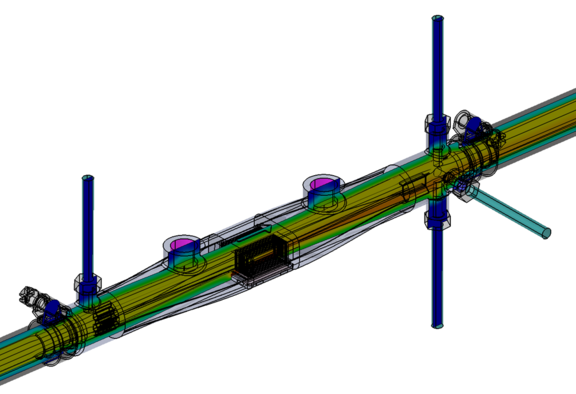

In the context of the project “Development of optimised cooling geometries using adjoint simulation methods for direct hot water cooling of data centres”, which is funded by the central innovation programme for small and medium-sized companies (ZIM) with funds from the BMWi, thermodynamically and hydraulically optimised cooling geometries are developed using computer-aided simulation methods. In addition to established tools such as FEM strength calculations, conjugated heat transfer (CHT) and the computational fluid dynamics (CFD) method, the project will also use adjoint simulation methods. The aim of the project is to test cost-efficient heat sink production to create a basis for achieving competitive investment costs compared to air-cooled data centres. To ensure this, the basic structure of the heat sinks (cooling channel) is intended to be made of plastic, with only the heat-transferring structures (cooling geometry) being made of metal with high thermal conductivity. The design and manufacturing process of the coolers is supplemented by behaviour simulations regarding the metal/plastic material combination. In particular, the behaviour of the different materials under thermal load and, if applicable, the resulting consequences on the material's fatigue resistance and the tightness of the heat sinks are intended to be investigated using the simulation tools.