Tool machine with hybrid Z-axis

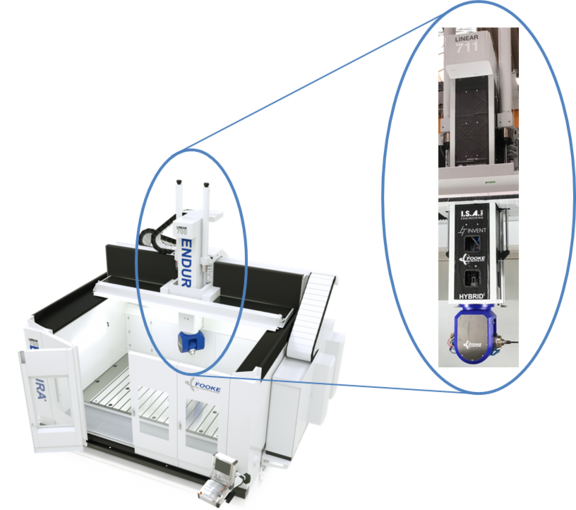

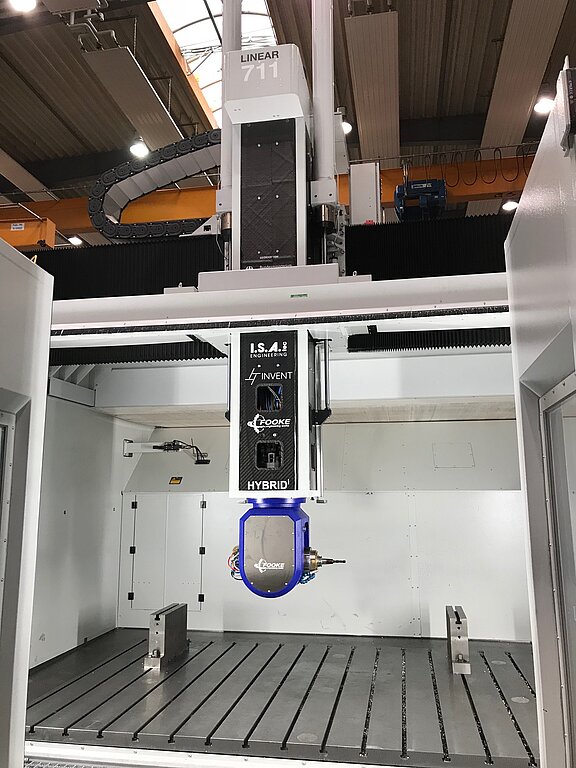

Hybrid lightweight structures are in demand in the automotive industry and increasingly in mechanical engineering for moving parts. The combination of conventional materials and fibre-reinforced plastic composites (FRP) provides enormous potential for increasing productivity. In the Fooke Endura 700 portal milling machine, the Z-axis is moved the most (left in the picture), therefore it was designed, calculated, built and tested in hybrid construction (right in the picture).

The concept consists of an FRP body that accommodates the components to be retained, such as the guide rails. The body itself was designed with high-stiffness carbon fibres, and a balanced structure in terms of materials was chosen for thermal stability. The hybrid Z-axis was installed in the machine and compared with the pure metal machine by means of various benchmark tests.

The result is a machine with significantly improved productivity: the mass of the Z-axis was halved while the natural frequencies were increased and thermal stability was significantly improved. On the whole, the dynamic properties were improved noticeably.