ISACAEP

ISACAEP is a tool developed in-house to calculate and optimise large welded structures.

To achieve a well-founded strength verification of large assemblies such as car bodies or rail vehicles frames, it is not uncommon for over a thousand joints to be evaluated.

The ISACAEP software developed by ISATEC relieves the user of much of this work and provides support throughout the entire calculation process, from model definition to evaluation and documentation. The program was designed to facilitate a quick pre-evaluation with conservative assumptions while simultaneously achieving a high degree of utilisation in terms of permissible limit values. On the other hand, the user has the possibility to carry out an evaluation with individual specifications. Results are documented consistently and traceably by ISACAEP.

The program uses the finite element software ANSYS® and works in the following steps:

- Automatic recognition of weld seams and assignment of meaningful numbering

Within an FE model, ISACAEP recognises all joints in a design. - Listing of all welded joints in the form of an Excel table (seam list) as well as visualisation

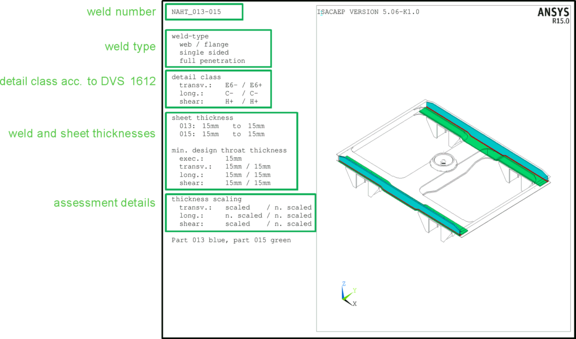

ISACAEP provides a simple procedure for defining fatigue classes. To this end, ISACAEP compiles all joints and their assessment parameters in an Excel table. Evaluation parameters such as seam type, layout and through-weld in combination with the planned seam cross-section can be edited in this table independently of ANSYS. Combined with automatically generated seam images, the designer is thus also able to define the seam parameters. - Automatic assignment of fatigue classes to weld seams according to DVS guidelines

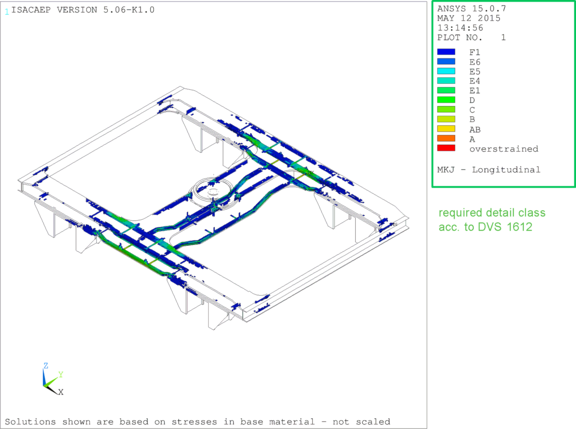

The parameters used for evaluation such as notch classes, reduction factors and calculated seam cross-sections are automatically assigned on the basis of the component catalogues of the DVS guideline. Alternatively, these parameters can also be set explicitly. - Evaluation of all seams

For each weld, ISACAEP evaluates the calculated load cases and determines the seam strength utilisation based on the seam parameters and local stress. For welds with a high stress level, further detailed evaluations are carried out (path evaluation to estimate local stress peaks). - Documentation

Weld seam definitions and the utilisation of all evaluation results with a utilisation above a freely definable threshold value are clearly documented in one result plot per seam.